Applications of Ceramic Band Heater

Ceramic band heater is widely used for high temperature industrial heating because it delivers excellent heat transfer efficiency, fast temperature rise and stable long-term performance.

This heating solution is the ideal choice for plastic processing machines, where precise temperature control is required

Plastic Injection Molding Machines

Main applications include:

Plastic Injection Molding Machines

Ceramic band heater is commonly installed on barrel zones of injection molding machines, helping melt plastic granules evenly, improving molding quality.Extrusion Machines

Used on plastic extruder barrels and die heads for stable heating during extrusion process. Ceramic band heater supports high temperature up to 800°C and ensures uniform melt flow.Blow Molding Machines

Helps maintain constant barrel temperature in blow molding process, which is critical for uniform wall thickness and good bottle clarity.Plastic Recycling & Pelletizing

Ceramic band heater is used for high temperature melting and regranulation of recycled plastics, improving output efficiency.Rubber Machinery & Tire Production

Provides stable heating on rubber processing machines to control viscosity and improve vulcanization performance.Food, Chemical, Packaging Industry

Some industrial drum heating and fluid processing systems also choose ceramic band heater for high power heating in limited space.

Plastic Injection Molding Machines

Main applications include:

Plastic Injection Molding Machines

Ceramic band heater is commonly installed on barrel zones of injection molding machines, helping melt plastic granules evenly, improving molding quality.Extrusion Machines

Used on plastic extruder barrels and die heads for stable heating during extrusion process. Ceramic band heater supports high temperature up to 800°C and ensures uniform melt flow.Blow Molding Machines

Helps maintain constant barrel temperature in blow molding process, which is critical for uniform wall thickness and good bottle clarity.Plastic Recycling & Pelletizing

Ceramic band heater is used for high temperature melting and regranulation of recycled plastics, improving output efficiency.Rubber Machinery & Tire Production

Provides stable heating on rubber processing machines to control viscosity and improve vulcanization performance.Food, Chemical, Packaging Industry

Some industrial drum heating and fluid processing systems also choose ceramic band heater for high power heating in limited space.

Why ceramic band heater is popular?

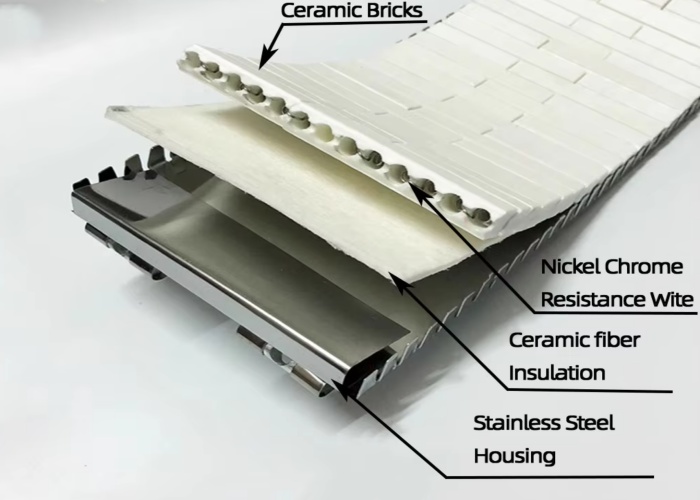

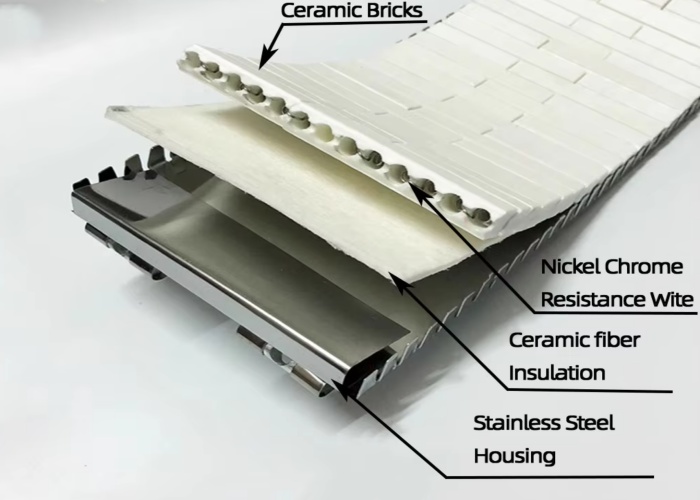

Compared with traditional mica band heater, ceramic band heater has:

higher temperature capability

lower surface loss

better energy efficiency

longer service life

So for modern plastic processing, ceramic band heater has become one of the mainstream industrial heating solutions.

Why ceramic band heater is popular?

Compared with traditional mica band heater, ceramic band heater has:

higher temperature capability

lower surface loss

better energy efficiency

longer service life

So for modern plastic processing, ceramic band heater has become one of the mainstream industrial heating solutions.

Recommended Ceramic Band Heater Products by Easewise

As a professional industrial heating solution supplier, Easewise recommends the following high-performance ceramic band heater models to improve your heating efficiency, reduce energy waste and support stable mass production.

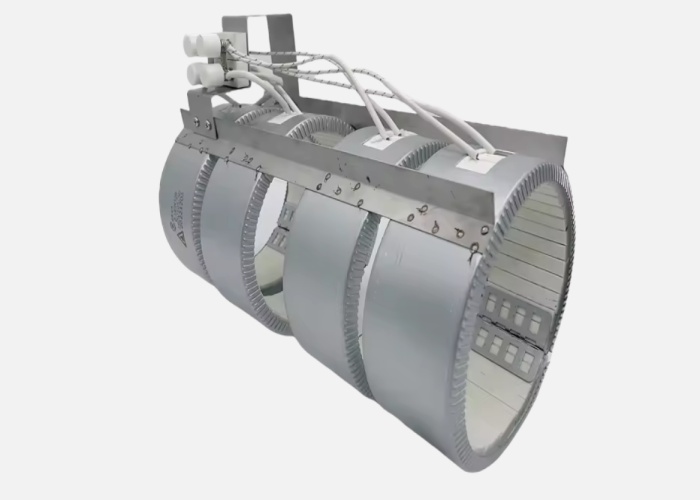

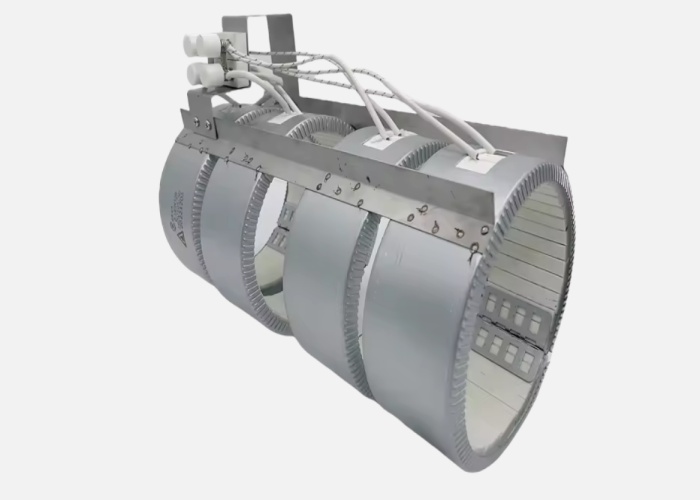

1) Easewise High Temperature Ceramic Band Heater – 800°C Grade

This model is built for long-term continuous high temperature production.

Max temperature: 800°C

Fast heat-up & uniform heating

Best performance for injection molding machines

Recommended for: automotive plastic parts, industrial plastic molding factories

2) Easewise Energy Saving Ceramic Band Heater with Insulation Jacket

This upgraded ceramic band heater comes with an insulation jacket to significantly reduce heat loss.

Save up to 20% – 30% energy cost

Lower machine surface temperature

Extend heater lifetime and reduce maintenance

Recommended for: extrusion lines, plastic recycling, 24/7 heavy duty production

3) Easewise Custom Size Ceramic Band Heater (OEM / Replacement)

Easewise offers complete customization service.

We support any diameter / any width based on your machine drawing or sample.

Support custom voltage & watt density

Suitable for extruders, blow molding machines & pelletizing machines

Recommended for: OEM customers & machine upgrading replacement projects

Recommended Ceramic Band Heater Products by Easewise

As a professional industrial heating solution supplier, Easewise recommends the following high-performance ceramic band heater models to improve your heating efficiency, reduce energy waste and support stable mass production.

1) Easewise High Temperature Ceramic Band Heater – 800°C Grade

This model is built for long-term continuous high temperature production.

Max temperature: 800°C

Fast heat-up & uniform heating

Best performance for injection molding machines

Recommended for: automotive plastic parts, industrial plastic molding factories

2) Easewise Energy Saving Ceramic Band Heater with Insulation Jacket

This upgraded ceramic band heater comes with an insulation jacket to significantly reduce heat loss.

Save up to 20% – 30% energy cost

Lower machine surface temperature

Extend heater lifetime and reduce maintenance

Recommended for: extrusion lines, plastic recycling, 24/7 heavy duty production

3) Easewise Custom Size Ceramic Band Heater (OEM / Replacement)

Easewise offers complete customization service.

We support any diameter / any width based on your machine drawing or sample.

Support custom voltage & watt density

Suitable for extruders, blow molding machines & pelletizing machines

Recommended for: OEM customers & machine upgrading replacement projects

Ceramic Band Heater for High Temperature Plastic Processing

Ceramic band heater provides fast heating, superb insulation, and stable high temperature control. Ideal for plastic injection molding machines, extruders and blow molding systems.

Get Quick Quote

Why Choose Ceramic Band Heater?

- Fast heat transfer with energy saving performance

- Max working temperature up to 760°C

- Excellent durability & thermal insulation

- Stable heating for continuous production

- Available in customized specifications

Ceramic Band Heater Applications

Ceramic band heater is widely used for high temperature plastic processing and industrial heating systems:

- Plastic injection molding

- Extruder barrel heating

- Blow molding machines

- Chemical & petrochemical heating

- Food processing equipment

- Pharmaceutical machinery

Technical Specification

Max Temp 760°C Wattage 30W – 6KW Voltage 110V / 220V / 380V / Custom Width 25mm – 300mm Diameter 25mm – 300mm

Request Price for Ceramic Band Heater

Tell us your size / wattage / voltage. We reply within 12 hours.

WhatsApp: 18883188154

Email: amy-easewise@tzheater.com

Contact Now

Ceramic Band Heater FAQ

What is ceramic band heater used for?

Ceramic band heater is used for plastic injection molding, extruders, blow molding and industrial heating applications.

Is ceramic band heater customizable?

Yes, we customize diameter, width, wattage, voltage and lead termination.

What's the temperature capability?

Ceramic band heater can work up to 760°C.

Ceramic Band Heater for High Temperature Plastic Processing

Ceramic band heater provides fast heating, superb insulation, and stable high temperature control. Ideal for plastic injection molding machines, extruders and blow molding systems.

Get Quick QuoteWhy Choose Ceramic Band Heater?

- Fast heat transfer with energy saving performance

- Max working temperature up to 760°C

- Excellent durability & thermal insulation

- Stable heating for continuous production

- Available in customized specifications

Ceramic Band Heater Applications

Ceramic band heater is widely used for high temperature plastic processing and industrial heating systems:

- Plastic injection molding

- Extruder barrel heating

- Blow molding machines

- Chemical & petrochemical heating

- Food processing equipment

- Pharmaceutical machinery

Technical Specification

| Max Temp | 760°C |

| Wattage | 30W – 6KW |

| Voltage | 110V / 220V / 380V / Custom |

| Width | 25mm – 300mm |

| Diameter | 25mm – 300mm |

Request Price for Ceramic Band Heater

Tell us your size / wattage / voltage. We reply within 12 hours.

WhatsApp: 18883188154

Email: amy-easewise@tzheater.com

Contact NowCeramic Band Heater FAQ

What is ceramic band heater used for?

Ceramic band heater is used for plastic injection molding, extruders, blow molding and industrial heating applications.

Is ceramic band heater customizable?

Yes, we customize diameter, width, wattage, voltage and lead termination.

What's the temperature capability?

Ceramic band heater can work up to 760°C.