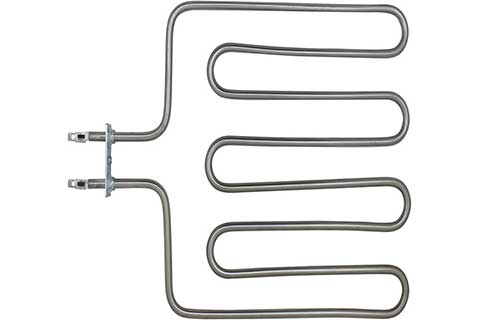

Tubular Heater

A tubular heater is a versatile and highly efficient heating element used in various industrial and commercial applications. It consists of a metal tube (usually made of stainless steel or Incoloy) that houses a heating element, typically a metal alloy wire, such as nichrome. The heating wire is wrapped around a ceramic core and sealed inside the tube. The tube serves as a protective sheath, ensuring the heater can endure high temperatures and adverse environmental conditions.

Get a quote today, and explore our full range of industrial heating products, including infrared, immersion, and pipe heaters.

Wide Application

Industrial heaters are vital across many sectors, from plastics manufacturing to food processing, metals, and oil industries. Their wide application helps ensure efficient and reliable operations, allowing businesses to improve productivity, meet quality standards, and minimize downtime. By offering customizable solutions, these heaters can be adapted to meet the precise needs of any industrial environment.

Medical & Healthcare

Industrial Heating

Energy & Environmental

Electronics & Home Appliances

Specification of Tubular Heater:

Efficient heating: Using high-quality resistance wires and high-density magnesium oxide powder, it has high thermal efficiency and rapid heating.

High temperature resistance: Metal tubes are made of various materials (such as stainless steel, titanium alloy, etc.), which can withstand high temperatures and adapt to different environments.

Corrosion resistance: Select different materials according to requirements, with good corrosion resistance, suitable for various media.

High mechanical strength: sturdy structure, pressure resistance, earthquake resistance, suitable for harsh working conditions.

Safe and reliable: Excellent insulation performance, equipped with overheat protection device to ensure safe use.

Material Options of Tubular Heater:

Parameters required for customers to place orders: (It is recommended to provide drawings or request order parameter drawings from customers for confirmation)

1. Voltage and power: customized according to the actual needs of customers.

2. Pipe diameter: commonly used pipe diameter is Φ 8-16mm.

3. Material: Common materials include 10 # iron SUS304。

4. Pipe length: refers to the length of the pipe body.

5. Total length: As shown in the figure, it refers to the total length of the terminal posts including both ends (fasteners).

6. Accessories: If fasteners are not required, customers must indicate.

Note:

If the customer does not have strict requirements, only the length parameters of the pipe body can be provided (fasteners and wiring parts are processed according to conventional procedures).

Benefits of Tubular Heater:

Energy saving and environmental protection: high thermal efficiency, reducing energy consumption.

Long service life: excellent material selection, advanced technology, and extended service life.

Widely applicable: suitable for various heating needs.

High cost-effectiveness: superior performance and reasonable price.

Tubular Heater Range

Tubular heaters are highly versatile, durable, and efficient heating solutions for a wide range of industrial applications. Whether you’re heating liquids, gases, or surfaces, tubular heaters offer excellent temperature control and energy efficiency. Their flexibility in design allows them to meet the specific needs of industries like plastic manufacturing, food processing, chemical processing, and HVAC systems. By choosing the right configuration and material, a tubular heater can provide long-lasting, reliable service in even the most demanding industrial environments.

Request a Quote

Learn More From

Frequently Asked Questions

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.