What Is a Hot Runner Heater?

Hot runner heaters are essential components in the injection molding process. They are designed to maintain the necessary temperature in the hot runner system, ensuring that the plastic material stays molten as it flows through the mold cavities. These heaters play a crucial role in the overall efficiency of the injection molding process, ensuring smooth production and reducing material waste.

Why Are Hot Runner Heaters Important?

Hot runner heaters are responsible for keeping the plastic material at the right temperature as it moves through the injection mold, which is vital for achieving the desired product quality. Without effective temperature control, the plastic can cool too quickly or unevenly, leading to defects in the final product. By maintaining a consistent temperature throughout the mold, hot runner heaters ensure that the molding process remains efficient and precise.

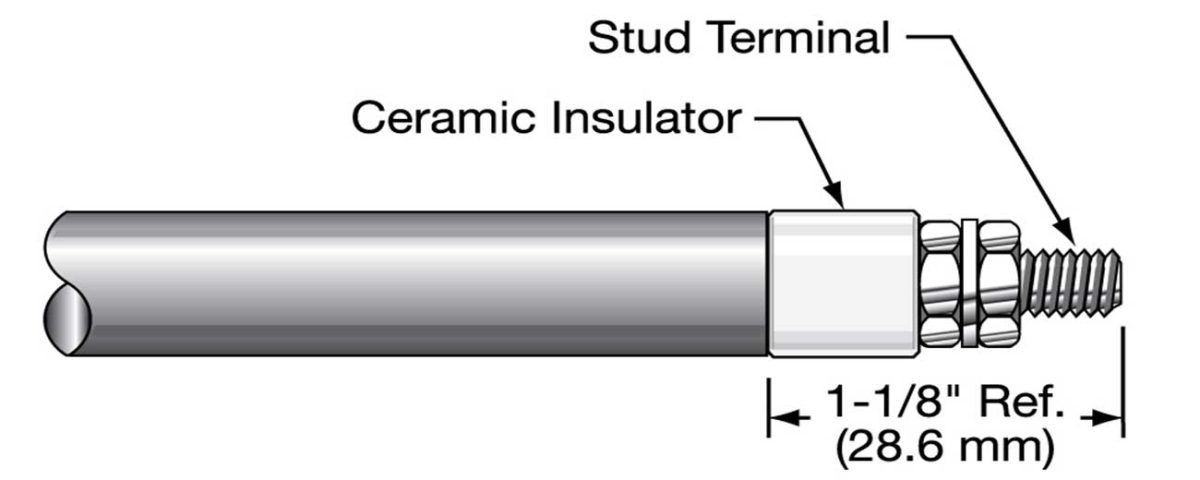

Tzheater’s hot runner heaters are made from high-quality materials like stainless steel or copper, with nichrome or other high-resistance wire inside. These materials are chosen for their durability and heat-resistance properties, which are crucial for the demanding conditions of injection molding. Available in various shapes and sizes, Tzheater’s hot runner heaters can be tailored to fit different mold designs and injection molding applications.

Advantages of Hot Runner Heaters

Energy Efficiency:

Hot runner heaters are designed to heat plastic precisely where it’s needed, directly in the mold. This localized heating minimizes heat loss, improving energy efficiency and reducing overall production costs. By maintaining the plastic in a molten state, the process becomes faster and more efficient, reducing cycle times.Precise Temperature Control:

These heaters help maintain a consistent temperature, which is vital for achieving high-quality molded products. The precise control of the temperature allows for better mold filling, reducing defects such as warping, flash, and other issues caused by uneven temperature distribution.Durability and Reliability:

Hot runner heaters are built to withstand high temperatures and mechanical stress during operation. Tzheater’s heaters are crafted from durable materials and are designed to last, offering reliability for continuous use in demanding manufacturing environments.

Factors to Consider When Choosing a Hot Runner Heater

When selecting the right hot runner heater for your application, several factors need to be considered:

Material Being Molded: Different plastics require different temperature profiles for optimal molding. The heater must be chosen to match the specific needs of the material.

Mold Temperature: The heater must be capable of achieving and maintaining the mold temperature required for the plastic to flow and set properly.

Injection Cycle Time: Faster cycle times require efficient heaters that can maintain the mold temperature quickly and consistently.

Mold Design: The shape and size of the mold cavities will determine the type and size of the hot runner heater that is best suited for the application.

Maintenance and Longevity of Hot Runner Heaters

Proper installation and regular maintenance are critical to ensuring the longevity and efficiency of hot runner heaters. Routine maintenance includes cleaning the heaters, inspecting them for any signs of damage, and replacing worn components as necessary. This not only extends the lifespan of the heaters but also ensures that the injection molding process remains smooth and uninterrupted.

Tzheater recommends conducting regular inspections of your hot runner heaters, especially after extended use, to identify any issues that could impact their performance.

Hot runner heaters are integral to modern injection molding technology, ensuring precise temperature control and efficient production processes. With Tzheater’s high-quality hot runner heaters, you can enhance the performance and longevity of your injection molding systems. By selecting the right heater and maintaining it properly, you can ensure high-quality products and cost-effective production.

Choose Tzheater for your hot runner heater needs and enjoy reliable, efficient solutions for your injection molding applications.