Introduction of Silicone Rubber Heater

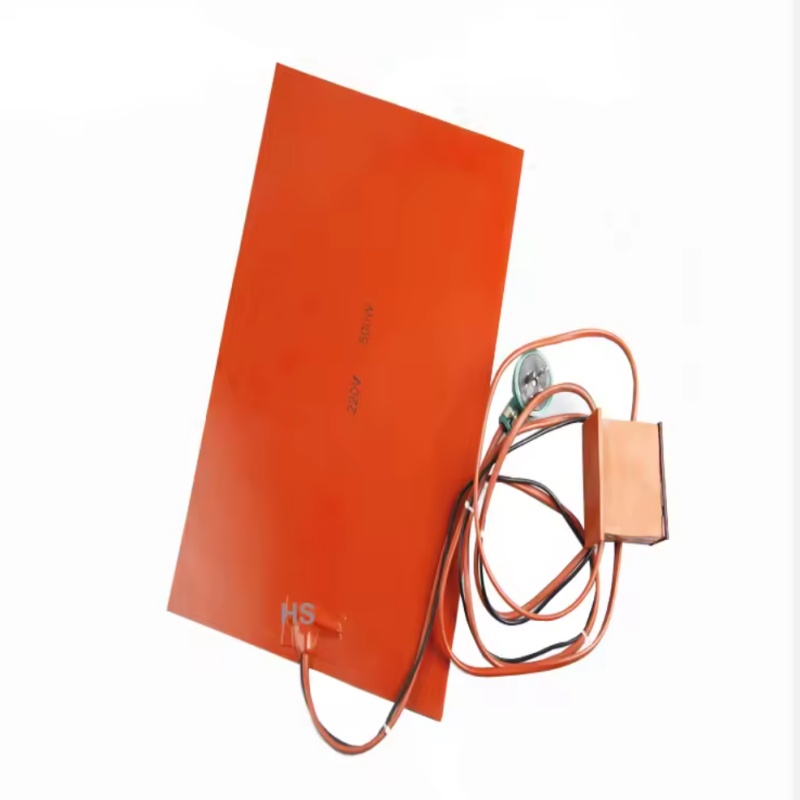

The silicone rubber heater plate (also known as silicone rubber heating plate or silicone heating sheet) is a flexible electrical heating device that combines nickel-chromium alloy heating elements with silicone rubber and glass fiber composite insulation layers. This innovative product has gained widespread adoption across multiple industries due to its unique combination of flexibility, durability, and efficient heating capabilities. As a soft, thin-film heating element, it can be custom-designed into various shapes and sizes, making it adaptable to diverse application requirements.

Key Features and Functions

- Customizable Design: The most significant advantage is their ability to be manufactured in virtually any shape or size. Whether circular, oval, conical, or completely custom geometries, these heating plates can be tailored to fit specific application requirements. This flexibility allows for optimal heat transfer to surfaces of any configuration.

- High Insulation Performance: The silicone rubber-glass fiber composite insulation layer provides exceptional electrical insulation, with breakdown voltages ranging from 20-50 kV/mm. This high insulation capability ensures safe operation even in demanding electrical environments, making it suitable for both industrial and medical applications.

- Excellent Thermal Properties: These heating plates offer rapid heating response, uniform temperature distribution across the surface, and high thermal efficiency.

- Durability and Longevity: Constructed with weather-resistant and chemical-resistant silicone rubber materials, these heating plates have a proven lifespan of up to ten years in continuous service. The materials are resistant to aging, moisture, and many chemicals, ensuring consistent performance over time.

- Easy Installation: Silicon rubber heater plates can be installed using various methods including adhesive backing, mechanical fastening, or even binding techniques. This versatility in installation options makes them adaptable to different application environments.

Applications

The silicone rubber heater plate exhibits an operational temperature range, capable of functioning effectively from -62°C up to 235°C. This wide range makes it suitable for applications requiring both low-temperature heating and high-temperature maintenance. The material’s ability to maintain its elasticity and electrical properties across this broad temperature spectrum is a key factor in its widespread adoption.

Industrial Applications

- Pipeline Heating: Used for freeze protection and temperature maintenance in industrial pipelines, particularly in chemical processing and oil refineries.

- Tank Heating: Provides efficient heating for storage tanks containing viscous materials that require temperature control.

- Industrial Equipment: Used as auxiliary heating for motors, pumps, and compressors to maintain optimal operating temperatures.

- Instrumentation: Provides precise temperature control for scientific instruments and industrial measurement devices.

Medical Applications

- Medical Devices: Used in blood analyzers, test tube heaters, and other laboratory equipment requiring precise temperature control.

- Therapeutic Devices: Incorporated into physiotherapy equipment and wearable heating products for medical treatment applications.

- Hospital Equipment: Used in sterilization equipment and other medical devices requiring controlled heating environments.

Aerospace Applications

- Aircraft Components: Used for de-icing and temperature maintenance of aircraft components exposed to extreme conditions.

- Spacecraft Systems: employed in temperature control systems for various spacecraft components due to their reliability and lightweight nature.

Consumer Electronics

- Battery Heating: Used in electric vehicles and portable electronics to maintain optimal battery temperatures in cold environments.

- Electronics Cooling: While primarily a heating device, it can be used in conjunction with cooling systems for temperature management in sensitive electronic components.

Other Applications

- Food Processing: Used in food storage and processing equipment requiring precise temperature control.

- Automotive: Used in vehicle heating systems, particularly for electric vehicles and hybrid systems.

- New Energy: Applied in solar energy systems and wind turbine components requiring temperature maintenance.

Conclusion

The silicon rubber heater plate represents a significant advancement in flexible electrical heating technology. Its combination of customizability, high performance, durability, and wide temperature range make it an indispensable component in numerous industrial, medical, and consumer applications. As technology continues to advance, we can expect to see further innovations in this field, including improved materials, enhanced integration with smart control systems, and expanded applications in emerging industries such as renewable energy and advanced robotics. With its proven track record and continuous technological evolution, the silicon rubber heater plate is poised to remain a key solution in temperature control applications for years to come.