Thermocouple Applications | Industrial Temperature Measurement Solutions

🔧 What Is a Thermocouple?

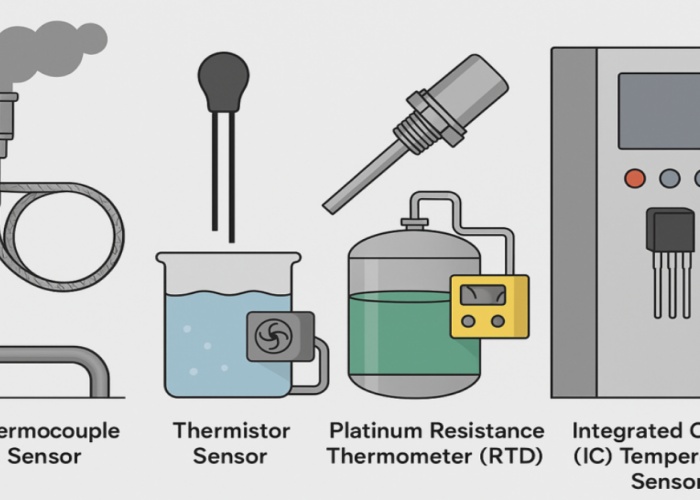

A thermocouple is a type of temperature sensor made from two dissimilar metal wires joined at one end. When the junction experiences a change in temperature, it generates a voltage that can be interpreted to measure temperature precisely.

Thermocouples are widely used across industries for their fast response, durability, and wide temperature range.

🌍 Thermocouple Applications in Different Industries

1️⃣ Plastic & Rubber Processing

In injection molding machines, extruders, and hot runner systems, thermocouples monitor and control barrel and mold temperatures to ensure consistent material flow and prevent overheating.

✅ Example: Type K and J thermocouples are commonly used in heaters and nozzles for real-time temperature feedback.

2️⃣ Industrial Furnaces & Heat Treatment

Thermocouples are essential in furnaces, kilns, and annealing ovens, where precise high-temperature measurement ensures product quality.

They withstand extreme temperatures, making them suitable for steel, glass, and ceramic manufacturing.

3️⃣ Food & Beverage Industr

Used in pasteurization, baking, and sterilization equipment, thermocouples maintain consistent heating levels to ensure food safety and quality.

✅ Example: Stainless steel-sheathed thermocouples provide corrosion resistance and easy cleaning.

HVAC & Energy Systems

In boilers, turbines, and solar heating systems, thermocouples help maintain efficient operation and prevent overheating or energy loss.

✅ Example: Thermocouples integrated with digital temperature controllers for automated system regulation.

Chemical & Pharmaceutical Processing

Accurate temperature control is vital in chemical reactors, distillation systems, and laboratory testing.

Thermocouples provide reliable readings even in corrosive or high-pressure environments.

✅ Example: Teflon-coated thermocouples for chemical corrosion resistance.

Related products

Thermocouple is one of the most widely used temperature sensing devices in industrial heating control. For different temperature range, response time and environment protection level, we offer multiple thermocouple models to help customers achieve reliable, accurate and stable temperature detection.

Below are recommended thermocouple solutions widely used in plastic machine, chemical plant, food processing line and industrial furnace system:

K Type Thermocouple (General Industrial Model)

Suitable for most extrusion machines, injection molding machines, packaging machine heating zones and barrel heating. Excellent cost-to-performance ratio and fast response.J Type Thermocouple (Stable Signal for Lower Temperature Zone)

Good for 0~750°C temperature range, commonly selected for plastic processing machines, dryers, and mid-temperature sealing machine heating control.N Type Thermocouple (Better Stability than K Type)

Suitable for long-term continuous temperature monitoring in harsh environment. More stable at high temperature than K type, ideal for furnace, petrochemical and continuous process line.High Temperature R/S Type Thermocouple (Up to 1600°C)

Platinum thermocouple used in high temperature industrial furnace, metallurgy, glass melting, ceramic sintering, and special heat treatment process.

Providing the right thermocouple selection ensures higher accuracy, faster response speed and longer service life of heating system. Contact our engineer to choose the correct thermocouple type, sheath material, probe diameter, installation thread, cable insulation and signal output for your equipment condition.

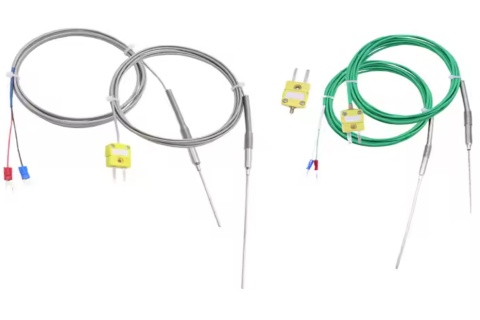

Thermocouple Probe for Injection Molding, Extruder & Industrial Temperature Sensing

Thermocouple probe is a high accuracy industrial temperature sensor used to measure real-time temperature inside molding machine barrel, extruder die head, industrial pipe and mechanical equipment. Available in K type, J type, T type and E type. Fast response, stable output, high repeatability and excellent long-term accuracy.

Get Quick QuoteWhy Choose Thermocouple Probe?

- Fast thermal response & stable temperature reading

- High accuracy suitable for industrial temperature control system

- Suitable for injection molding & extruder barrel temperature measurement

- Available in K, J, T, E type thermocouple

- Custom probe length, sheath material, thread and lead wire options

| Thermocouple Type | Temp Range | Accuracy | Advantages | Typical Application for Thermocouple |

|---|---|---|---|---|

| K Type | -200°C to 1260°C | ±2.2°C / ±0.75% | Low cost, wide compatibility, most universal | Extruder, injection molding, industrial heater control |

| J Type | -40°C to 750°C | ±2.2°C / ±0.75% | Higher sensitivity, affordable | Medium temperature industrial heating |

| T Type | -200°C to 350°C | ±1°C / ±0.75% | High accuracy at low temperature | Food, pharmaceutical, low temperature measurement |

| N Type | -200°C to 1300°C | ±2.2°C / ±0.75% | Better stability & corrosion resistance | High temperature industrial thermocouple |

| R / S Type (Noble Metal) | 0°C to 1600°C | ±1.5°C / ±0.25% | Ultra high temperature, high precision | Special extreme high-temperature process |

Thermocouple Probe Mounting & Thread Options

We offer multiple mounting and thread options to fit different industrial machine installation methods. Standard machining accuracy ensures reliable sealing and fast replacement.

| Thread Type | M6, M8, M10, NPT1/8", NPT1/4" |

| Mounting Style | Straight probe type / 90° angle probe |

| Fixing Accessories | Compression fitting / Adjustable bayonet cap / Spring-loaded bayonet locking |

| Cable Exit Direction | Straight exit / Side exit / 90° back exit |

| Connector Option | Mini plug / Standard plug / Terminal block / Bare wire |

Thermocouple probe can be supplied with bayonet fitting for injection molding machine, screw thread for pipe temperature measurement or compression fitting for high temperature sealing application.

Thermocouple Probe Applications

Thermocouple probe is widely used for industrial process temperature measurement, especially where fast response and accurate sensing are required:

- Injection molding machine barrel temperature monitoring

- Extruder die head & cylinder temperature sensing

- Plastic processing & rubber processing temperature control

- Industrial heating equipment & chemical process measurement

- Pipe temperature measurement and mechanical equipment

Recommended Thermocouple Products

Below are the most popular thermocouple probe types for industrial temperature sensing. Suitable for extruder, injection molding machine, furnace, food machine, chemical processing and general industrial heating systems.

- Industrial K Type Thermocouple Probe – Fast response, stable accuracy, universal industrial use.

- Stainless Steel Armored Thermocouple Sensor – Strengthened cable protection for harsh environments.

- High Temperature Thermocouple Probe up to 1200°C – Designed for furnace, kiln and high-heat systems.

- Threaded Thermocouple Probe with NPT/BSP Fitting – Easy fixed installation for equipment and pipeline.

| Model | Temperature Range | Material | Application |

|---|---|---|---|

| K Type Thermocouple Probe | 0°C – 800°C | SS304 | Extruder / Injection machine |

| Armored Thermocouple Sensor | 0°C – 900°C | SS304 + SS braided armored cable | Outdoor / chemical / harsh environment |

| High Temp Thermocouple Probe | 0°C – 1200°C | SS310 / Inconel optional | Furnace / kiln / thermal processing |

| Threaded Thermocouple Probe | 0°C – 850°C | SS304 + NPT/BSP thread | Pipeline / machine fixed installation |

Contact us now for custom thermocouple probe design, fast quotation and global shipping.

Get Custom Thermocouple QuoteWe supply thermocouple sensors in multiple thermocouple types including K, J, T, E and N type thermocouple. Each thermocouple probe is designed for different temperature ranges, accuracy classes and industrial heating conditions. Thermocouple type K is the most commonly used version for extruder, injection molding machine, industrial heater, drying oven, furnace and processing equipment. Available with threaded fitting, armored cable, mineral insulation and stainless steel sheath.

Thermocouple Probe Technical Specifications

Below are standard technical parameters for industrial thermocouple probe. We support custom type, sheath material, cable insulation and thread.

| Thermocouple Type | K / J / T / E |

| Measuring Range | K type: -200°C to 1100°C / J type: -150°C to 750°C |

| Accuracy Class | Class 1 / Class 2 (IEC60584) |

| Probe Construction | Grounded junction / Ungrounded junction / Exposed junction |

| Sheath Material | 304SS / 316SS / Inconel |

| Probe Diameter | Φ1mm – Φ8mm |

| Lead Wire Insulation Options | Fiberglass / PTFE / Stainless Steel Braid / Shielded Cable |

Thermocouple probe is optimized for high sensitivity and stability in industrial automation and extrusion temperature measurement.

| Thermocouple Type | Temperature Range | Typical Application |

| Type K Thermocouple Probe | -200°C ~ 1260°C | Injection molding machines, extruder screw temperature control, high temperature industrial heating |

| Type J Thermocouple Probe | -40°C ~ 750°C | Metal processing line, older equipment replacement, industrial ovens |

| Type T Thermocouple Probe | -200°C ~ 350°C | Food industry, laboratory temperature sensing, low temperature industrial process |

Request Price for Thermocouple Probe

Tell us thermocouple type / probe length / diameter / material / cable type. We reply within 12 hours.

Contact Amy: +86 18883188154 | amy-easewise@tzheater.com

Contact Hanna: +86 17351636811 | hanna-easewise@tzheater.com

Contact NowThermocouple Probe FAQ

Where is thermocouple probe used?

Thermocouple probe is used in injection molding machine barrel, extruder die head, industrial pipe and mechanical equipment.

Can thermocouple probe be customized?

Yes. We support custom type (K/J/T/E), probe diameter, sheath material and cable insulation.

What is the temperature capability?

K type thermocouple probe supports up to 1100°C.

Recommended Temperature Measurement Products

K Type Thermocouple

High accuracy for general-purpose temperature measurement.

PT100 RTD Sensor

Ideal for precision low-temperature applications.

Thermowell Protection Tube

Protects sensors from high pressure and corrosion.

Temperature Controller

Ensures accurate process temperature regulation.

Thermocouple Compatible Products & Applications

Explore related industrial heating and temperature sensing solutions designed to work seamlessly with thermocouples.

Cartridge Heater

High-performance cartridge heater used with thermocouples for precise mold and die heating.

Explore Cartridge Heater Applications →RTD Sensor (PT100/PT1000)

Accurate and reliable RTD temperature sensors for industrial monitoring and thermal control.

View RTD Sensor Details →